Institute for Machine Elements at the University of Stuttgart detects smallest fracture on gear flank surface with the help of a SONOTEC ultrasound sensor.

Recognize Bearing Damage early with Ultrasound

The intelligent networking of machines plays a crucial role in Industry 4.0. As a result, many machines are equipped with condition monitoring systems. Sensor data recorded on the machine is used to make statements about the condition of the machine or individual critical components. Condition monitoring detects damage at an early stage, so that unexpected machine failures can be prevented. For machine engineers, this results in added value in terms of operational safety as well as a financial advantage.

In the event of a gearbox malfunction, it can lead to an entire machine coming to a standstill. For this reason, gearboxes are particularly suitable for condition monitoring during operation. The main failure mechanisms of gearboxes show a gradual progression of damage. It is therefore possible to detect damage early before it reaches a critical stage. As soon as damage has been detected and the condition of the damage has been identified, the remaining service life of the gearbox can be estimated.

Current research investigates pitting damage

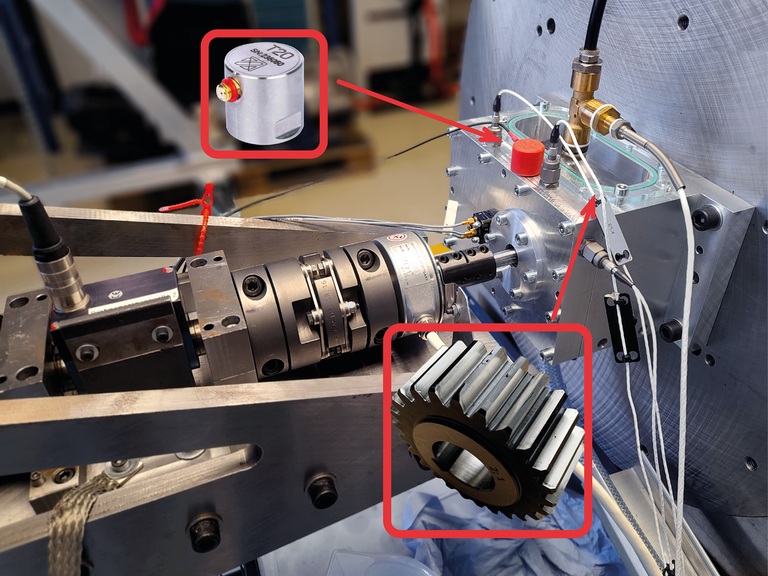

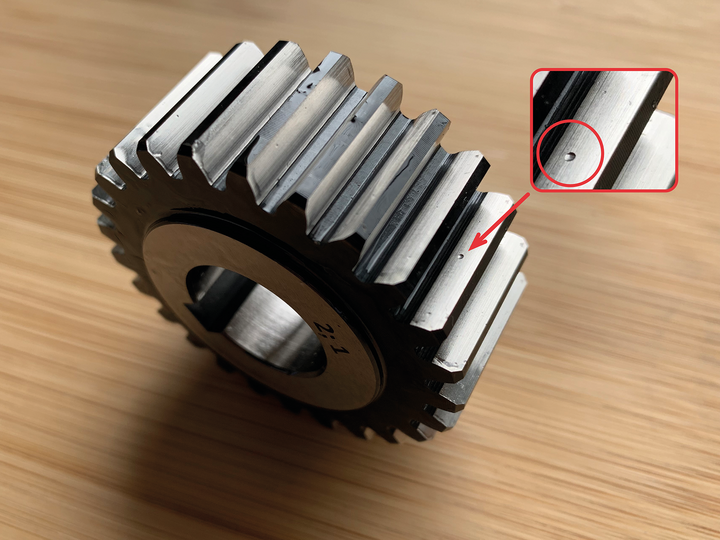

The focus of current research at the Institute for Machine Elements at the University of Stuttgart is on pitting damage. In cooperation with SONOTEC, a measurement technology manufacturer specializing in ultrasound, pitting damage on gears was investigated. In the process, damage could be detected well before the failure criterion standardized in DIN 3990-5 which is of an area fracture on a tooth flank surface of 4%. This is possible with suitable sensor technology. In a series of tests, synthetic pitting damage with area fracture between 0.4 % and 2 % of the area of a tooth flank was examined. In addition to the size of the pitting damage, the speed, torque, and lubricating oil viscosity were systematically varied in the tests. In this way, the detection capability of the pitting damage could be tested under different boundary conditions. Different accelerometers were used to collect sensor data during operation of the gears with pitting damage. Compared to the accelerometers, the pitting damage is clearly visible in the measured data of the T20 structure-borne sound probe from the manufacturer SONOTEC. Particularly in the ultrasonic frequency range above 16 kHz, the pitting damage is clearly detectable with the T20 structure-borne sound probe from SONOTEC. Thus, it is possible to reliably detect even the smallest examined pitting damage with area fracture of 0.4% of the area of a tooth flank.